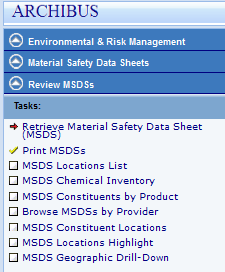

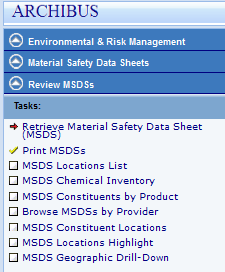

MSDSs provide employees with specific information on the chemicals they use. In this scenario, the safety and health manager maintains data in the ARCHIBUS MSDS application as well as a hard-copy binder in his office with an MSDS on every substance on the company's list of hazardous materials. The plant manager ensures that each work site maintains MSDSs for the hazardous materials in each work area and that each employee has immediate access to MSDSs via computer terminal or hard copy. MSDSs are also readily available to employees at their work stations. In the MSDS application, the Review MSDSs process provides several different ways to view MSDS information. Different users of the system have different information requirements. In this use case we look at the two heaviest users of the system, The Safety and Health Manager and the general employee.

Whether for training or in response to an emergency, a user should be able to quickly and easily retrieve full details for the MSDS (especially the manufacturer’s original document). While this information is available in several places, the primary tool for this is the “Retrieve MSDS” task. This view allows the user to search the complete MSDS inventory based on whatever information he may have. For example, an employee or an emergency responder might arrive at the scene of an accident or injury involving some chemical and they do not know all the details. Maybe they know the room or think it could have been from several different rooms. So they can enter what they know to get a list of possibilities. On the other hand, if they can clearly identify the product on site and have its name, then they might filter directly to that entry. This view provides quick access to the manufacturer's original MSDS via the View MSDS button and 5 tabs organize the detailed information for ready access to what you want to know simply by clicking on the tab:

In a more typical scenario than the emergent need for information described above, employees would be accessing MSDSs in the development stages of some type of integrated safety planning where they are defining procedures and or processes that use hazardous materials. Access to the information in the MSDS allows the process to be engineered with regard to the specific hazards and requirements of the materials involved in the process. In this case, an engineer would use the "Retrieve MSDS" task to obtain the MSDSs for the materials of interest. He would review the data and include requirements for things such as personal protective equipment, fire protection measures, and evacuation planning. Often copies of the MSDSs are incorporated into the written procedure or safety plan. The engineer could use the "Print MSDSs" task to accomplish this. Another possibility in the planing would be that the engineer might need to know what other hazardous materials are present where the work is to be accomplished. For example one of the materials to be used in the process may indicate that it should not be used in proximity to oxidizing agents. The engineer could review "MSDS Constituent Locations" to determine if there are potential issues performing the process in the proposed location.

The safety and health manager, responsible for acquiring and updating MSDSs, contacts the chemical manufacturer or vendor if additional research is necessary or if an MSDS has not been supplied with an initial shipment. He may use the “Retrieve MSDS” report to quickly search for an MSDS for which he requires more information from the manufacturer. The report will show contact information for the manufacturer. Alternately, he may view the “MSDS Details by Provider” report to retrieve manufacturer contact information. Since all new procurements for the company must be cleared by the safety and health manager, he is able to keep the master list of MSDSs current. A master list of all MSDSs can be generated using the “Retrieve MSDS” report and selecting the XLS button in the MSDS panel.

In addition to maintaining the inventory of hazardous materials, the safety and health manager is responsible for ensuring that all hazardous chemicals in the plant are properly labeled and updated, as necessary. Note: this requirement applies especially to cases where chemicals may be used/stored in containers other than the ones provided by manufacturers. For example, a large storage tank, small spray bottle, or a piece of equipment. Minimum labeling requirements are: the chemical identity, appropriate hazard warnings, and the name and address of the manufacturer, importer or other responsible party. ARCHIBUS MSDS stores this information and can be used in verifying label information during activities such as safety walk-around, chemical inventory review, and shipment inspections when containers are shipped from the plant.

Several other reports included in the Review MSDSs process may be applicable to tasks performed by the Safety and Health Manager.