In order to get started with the MSDS application, you will need an inventory of the hazardous materials used at your facility. The list should identify the material, the manufacturer, the supplier, the location where the material is used, and the location where the material is stored. Every manufacturer of a potentially hazardous material is required to provide a standard set of information that is included in the MSDS. This information can be obtained from the manufacturer, or the supplier, or may be available in a library of MSDS information. As you are generating your inventory, you may want to note your source for the MSDS.

The minimum regulatory requirement is that a copy of the MSDS for all hazardous materials in use must be readily available in the locations where it is used and where it is stored. This minimum requirement could be accomplished by simply having a binder of printed MSDSs in close proximity. If you are dealing with a limited number of hazardous materials and very few locations, this approach might work. However, it is more common for facilities to have hundreds or thousands of hazardous materials that are used and stored in many locations throughout a site. Consider a substance such as toilet bowl cleaner -- a common cleaning agent that may be present in every janitorial closet in the facility. The binder method requires a lot of leg work to get the MSDS to the location and then continual review to make sure no one walked off with the binder or tore the toilet bowl cleaner MSDS sheet out. So if all you do is enter identifying information and upload the MSDS, you are ahead of the paper process because personnel can access the MSDS from anywhere there is a network-connected workstation.

Further benefits can be gained by expanding on the basic "identify and catalog" approach. In addition to storing the manufacturer's MSDS, the MSDS application allows you to associate MSDSs with specific locations in your facility -- as general as a complete building or floor, or as specific as a room. Now you have the power to locate those hazardous materials using several different methods.

Going further into the data, you can also enter the hazard classifications, constituent chemicals, and physical properties associated with each MSDS. Having these data gives you more capabilities for evaluating potential hazards, assisting during an emergency response, locating specific chemicals, and generating chemical inventory reports. Most of the time, these additional data are readily available on the manufacturer's MSDS, so additional research is not typically needed.

The beauty of the system is that you don't have to enter all of the detail at the outset. If it makes more sense for you to start out slow and just enter the identifying information and load the manufacturer's MSDS, that's all you really have to do. You can tackle the additional information in separate phases. It would make sense to add location information in another phase and follow that with an application to get the detailed information entered. The more information you can detail in the system the better will be your ability to analyze and quantify hazards at your facility.

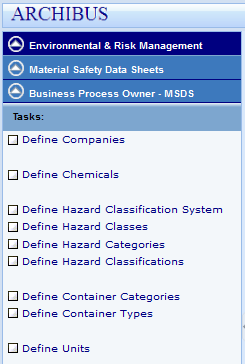

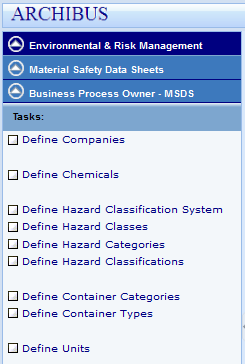

The process of entering MSDSs will be more streamlined if the background data are entered into the system first. Once you have identified your initial objectives, you will want to make sure the appropriate background data are in the system. These background data are managed in the task Business Process Owner - MSDS and include company, chemical, hazard classification, container and unit data.

Part of the data collected while compiling the list of hazardous materials is the company who provided the material and/or the manufacturer. The data elements are needed for reporting on the inventory and for contacting the provider to get updated MSDS information. The task Define Companies is used to enter manufacturer and supplier information.

An important component of the manufacturer's MSDS is the chemical constituents of the hazardous material. These constituents are needed for chemical inventory reporting. In order to assign the constituent chemicals to an MSDS, you need to have the chemicals in a reference list. The MSDS application ships with a "sample" list of chemicals. This list is not intended to be comprehensive and is provided as a courtesy without warranty for accuracy. It is recommended that you review these data for completeness and relevance to your facility. While you don't need a complete list of constituent chemicals at the outset, without a doubt, you will need to add chemical constituents to this list as you progress through the entry of your MSDSs. Chemical data are entered via the task Define Chemicals.

In addition to the constituents of the hazardous material, the MSDS identifies the hazards associated with it. Hazards are used to quantify how dangerous the substance is. The particular hazards associated with the material determine how it must be handled and stored and may have a bearing on treatment if is a user is exposed. There are a number of hazard classification systems in use. You will need to identify the systems used at your facility and document those in the MSDS application as background data. The MSDS application ships with four classification systems included.

If you choose to use these classification systems, make sure you review the definitions for consistency with the classification system specified for your site.

Several tasks under Business Process Owner: MSDS can be used to enter and/or edit classification systems. These tasks define a classification hierarchy from top to bottom:

The view Define Hazard Classifications provides the ability to define all 3 levels on the same form.

Container categories and types are used when assigning an MSDS to a location. It is important to know the size of the container for chemical inventory reporting. The attributes of the container type provide container size information. Two tasks provide the views to enter and modify Container data: Define Container Categories and Define Container Types.

In addition to specifying the container type when assigning MSDSs to a location, the quantity of the material can be recorded to be included in actual inventory and capacity reporting. In order to accommodate units in the system of choice for your site, RACHISS provides a method for defining applicable units. Use the Define Units task for specifying units.

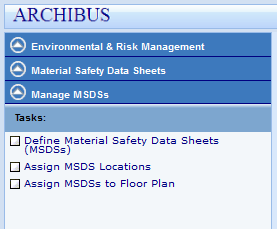

In general, facilities need a separate list of hazardous materials for each work area. Each list identifies the corresponding MSDS for each material. The safety and health manager is responsible for maintaining a master list of these materials. In the ARCHIBUS MSDS application, the “Define MSDS (Material Safety Data Sheet)” task is used to enter definition and identification information for each material. Then “Assign MSDS Locations” or “Assign MSDSs to Floor Plan” can be used to enter multiple storage and/or usage locations for the MSDS.

The hazardous materials list must be available to all employees where that material is used or stored. In the ARCHIBUS MSDS application, “Browse MSDSs by Location” task provides convenient access to employees. In addition, employees can obtain a printable list of products to post at the location. Users can also access the MSDSs for the location by signing in to ARCHIBUS and using “Retrieve MSDS” to perform a search.

Note: This use case script assumes certain background data already exists in the project database. Ideally, users will have already defined items such as manufacturers, hazard classifications, container categories and types, and chemical ingredients.

The process Manage MSDSs provides the access point to the tasks needed for defining MSDSs and assigning them to locations.

Typically facilities will keep a hardcopy of the MSDSs for all of the materials used in a location. The hard copy guarantees that workers can access the MSDS information even if the computer is down. It is also a backup for cases where someone may not be authorized to access the computer. To prepare a list of chemicals at a location use the “Print MSDSs" task.